|

Welcome to the Fatigue Testing & Advanced Manufacturing Lab (FTAM LAB)

|

|

|

• Metal Fatigue

• Fracture Mechanics

• Additive Manufacturing

• Multiaxial Fatigue

• Failure Analysis

• Materials Mechanical Behavior

|

• Fatigue of Polymers

• Biomedical Implant Design

• Mechanical Behavior of Bone

• Composite Materials

• Damage Mechanics

• Mechanical Design

• Experimental Mechanics

|

|

Assistant Professor of Mechanical Engineering |

|

|

Ebrahim Seidi, Ph.D. Assistant Professor of Mechanical Engineering |

|

MONOTONIC TESION TESTING

Basic mechanical properties of materials can be obtained using a simple monotonic

tension test. Properties such as elastic modulus, yield strength, ultimate strength,

fracture stress, ductility, and elongation at break.

FATIGUE TESTING

Fatigue Testing measures the ability of samples to withstand the application of repeated

load cycles to determine their stress limit with the corresponding life.

FRACTURE TOUGHNESS TESTING

Fracture Toughness Testing provides information about a material’s resistance to crack

extension under a steadily increasing load.

FATIGUIE CRACK GROWTH TESTING

Crack growth testing involves subjecting materials to cyclic loading conditions to

analyze the propagation rate of cracks, providing critical data for assessing the

fatigue resistance and durability of the material.

HARDNESS TEST

Perform indentation on the sample, creating permanent deformation, to evaluate the

material’s strength, ductility, and wear resistance.

FRACTOGRAPHY

Evaluate the fracture surface of the sample to determine the cause and analyze the

failure in the engineering structure.

FRACTURE TOUGHNESS TESTING

Also known as the stress-relaxation test. Supply a constant load at a constant temperature

over a period of time to determine the strength and heat resistance of a sample’s

material.

1. FATIGUE TESTING SYSTEM

EHF-E SERVOPULSER, 50KN, ± 50 mm from Shimadzu

Features include:

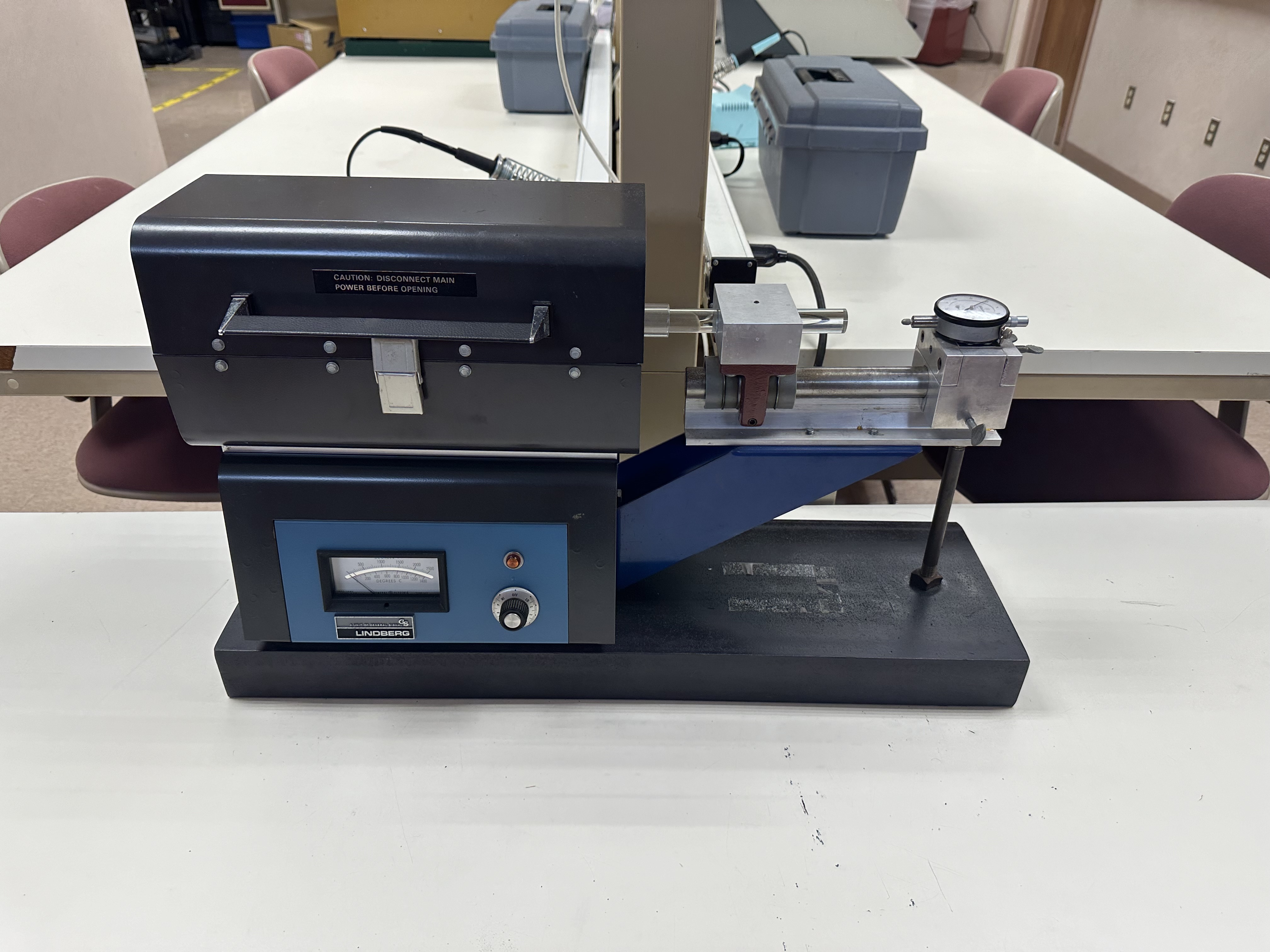

2. ROTATING BENDING

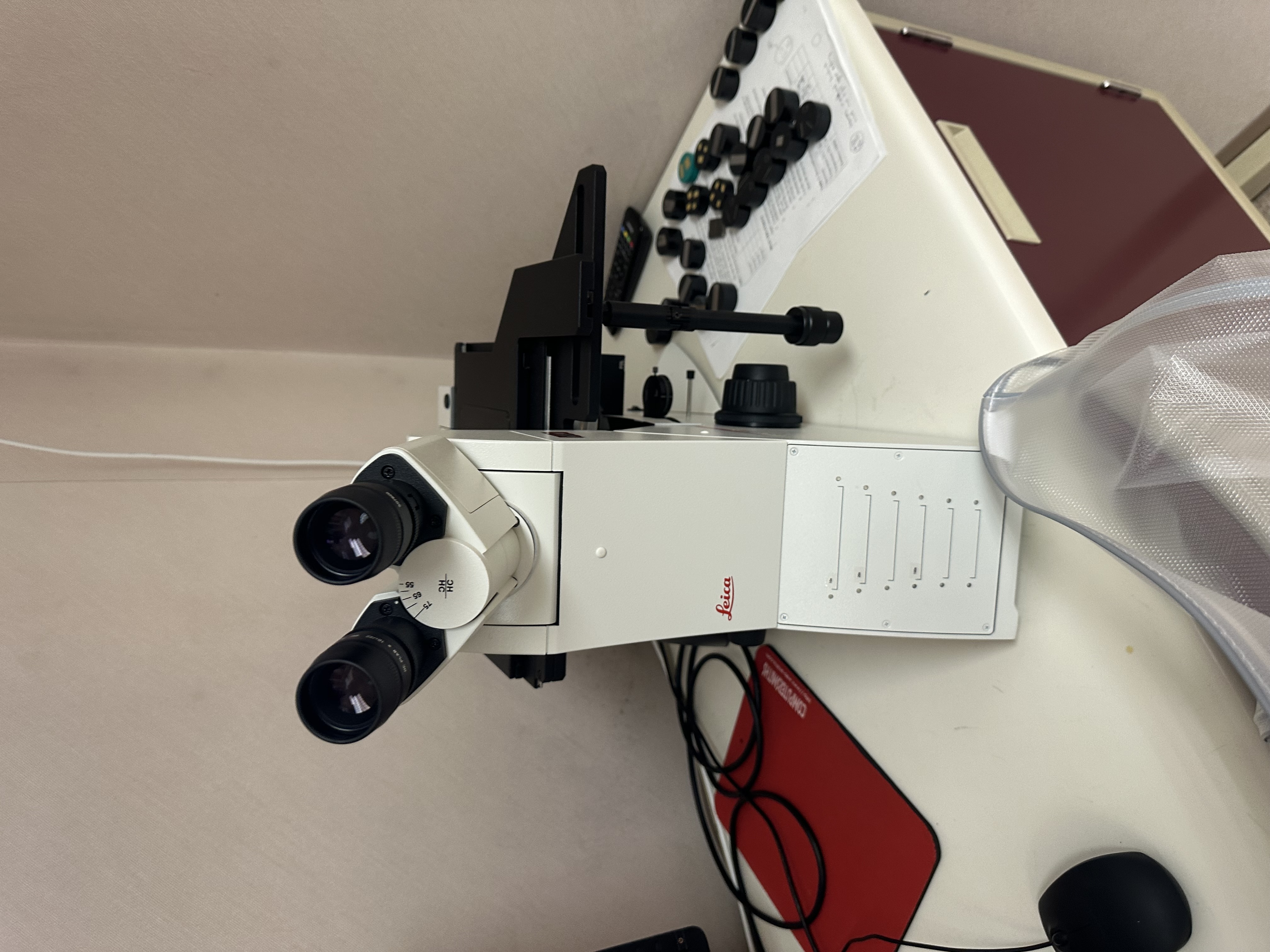

3. OPTICAL MICROSCOPE

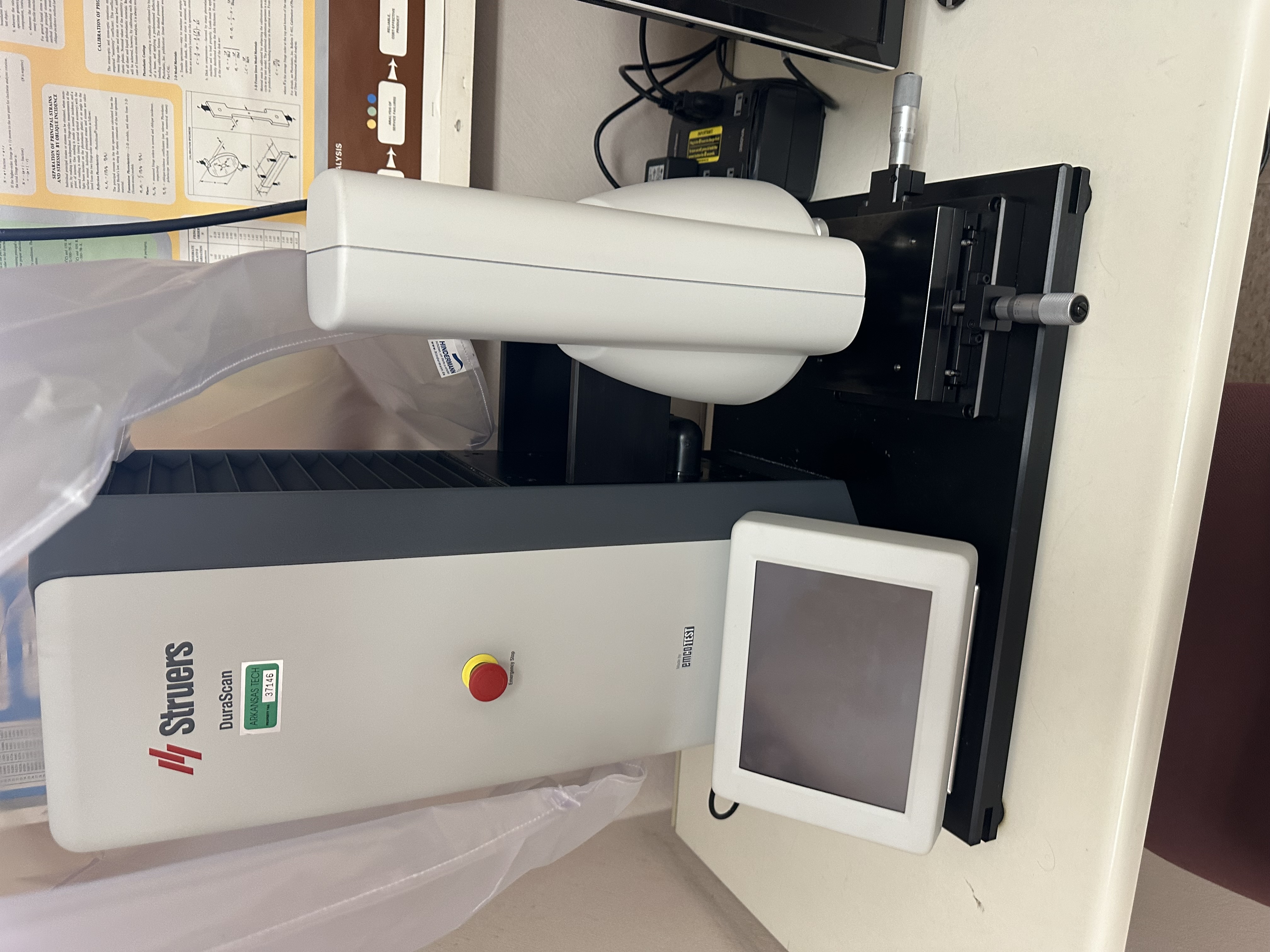

4. HARDNESS TESTER

5. INFRARED CAMERA

|

|

Mohammad Amjadi, Ph.D. Assistant Professor of Mechanical Engineering |

|