Welcome to Fatigue & Fracture Lab

"We Break To Build Better"

|

Mission:

Vision:

Who We Are:

What We Do:

|

|

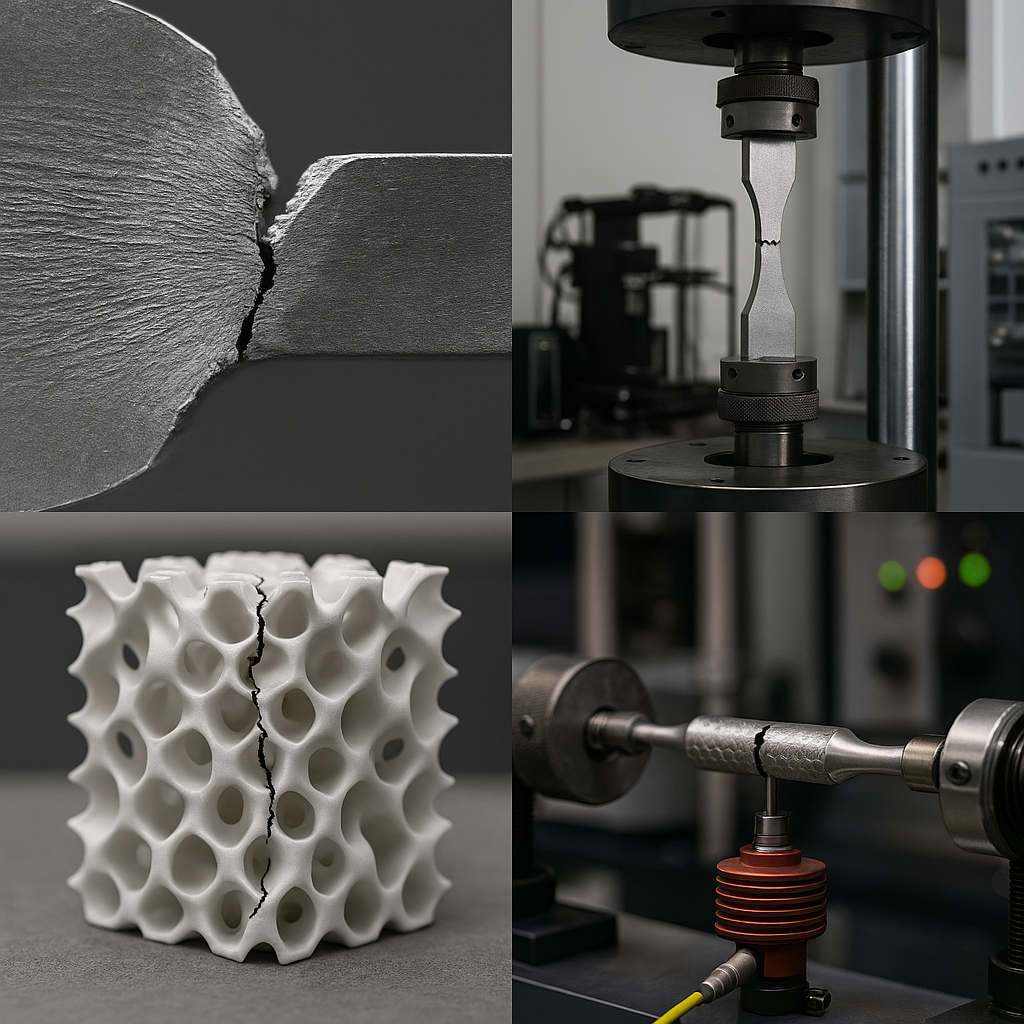

We generate reliable fatigue and fracture data to help engineers design safer components.

Our team specializes in coupon-level testing, analysis, and modeling for metals, thermoplastics,

and carbon-fiber reinforced polymers including FFF/AM materials. We partner with industry

and agencies to turn rigorous experiments into actionable S–N/ε–N curves, design allowables,

and failure insights.

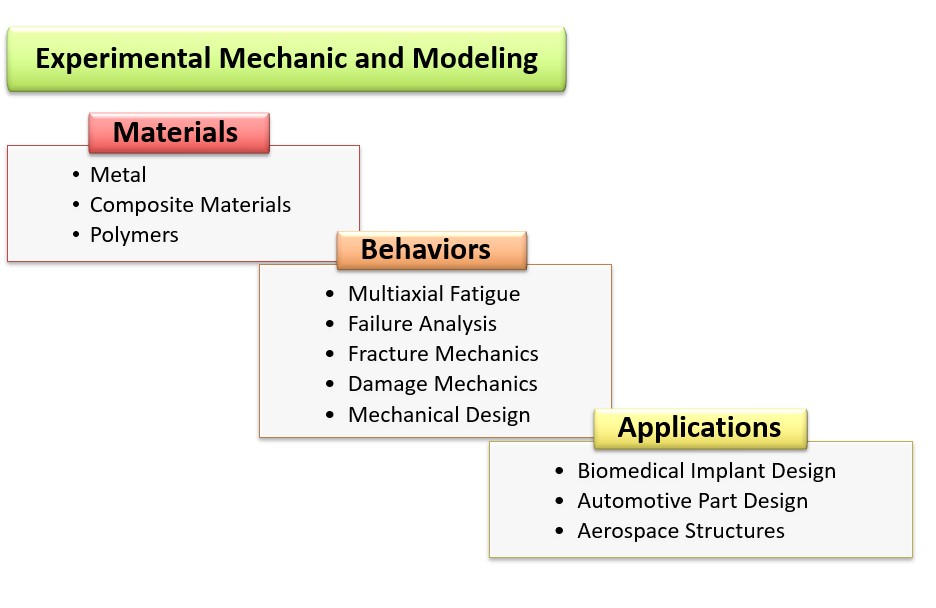

Research Area:

|

- Fatigue & Fracture Mechanics

Advanced concepts in fatigue behavior, fracture mechanics, and life prediction with applications in structural design. - Additive Manufacturing for Mechanical Engineers

Fundamentals of design for additive manufacturing, processes, and structural performance of additively manufactured metals, polymers and composites. - Machine Design Components

Principles of mechanical component design, stress/strain analysis, and reliability under static and fatigue loading. - Finite Element Analysis (FEA)

Introduction to computational modeling, stress analysis, and design optimization using commercial FEA software. -

Composite Materials

Study of fiber- and particle-reinforced materials, including mechanical behavior, micromechanics, failure modes, and applications in aerospace, automotive, and biomedical fields.

|

Lab Director: Assistant Professor of Mechanical Engineering |

|

|

Former Students: Brayden May (Currently Tooling and Process Engineer at Taber Extrusions) Brayden May is undergraduate alumni, majoring in Mechanical Engineering. His research focused on the fatigue behavior of 3D-printed thermoplastics, contributing to advancements in additive manufacturing techniques and material durability testing. |

|

|

Minh Tran (Currently Development Engineer at First Solar) Minh Tran is a Mechanical Engineering graduate student doing research on fatigue behavior of porous titanium and thermoplastic cellular structures. Minh's research aims to enhance the performance and durability of materials used in advanced engineering applications. In addition to his academic work, Minh gained valuable industry experience during a summer internship at AESC US headquarters in Smyrna, Tennessee. As an electric vehicle (EV) and energy storage systems (ESS) battery cell process engineer intern, Minh developed an automated packaging machine capable of processing 15 battery cells per minute, improving efficiency and safety. |

|

|

Genya Ohama: A Bachelor's student majoring in Mechanical Engineering at Arkansas Tech University, conducted fatigue testing experiments on 17-4 Stainless Steel material produced by binder jetting. |

|

Service

|

Standards-Aligned Methods (e.g., ASTM E466 axial fatigue, ASTM E606 strain-controlled fatigue; ASTM D7791-style methods for polymers/composites where applicable) MONOTONIC TESION TESTING FATIGUE TESTING FRACTURE TOUGHNESS TESTING FATIGUIE CRACK GROWTH TESTING HARDNESS TEST FRACTOGRAPHY |

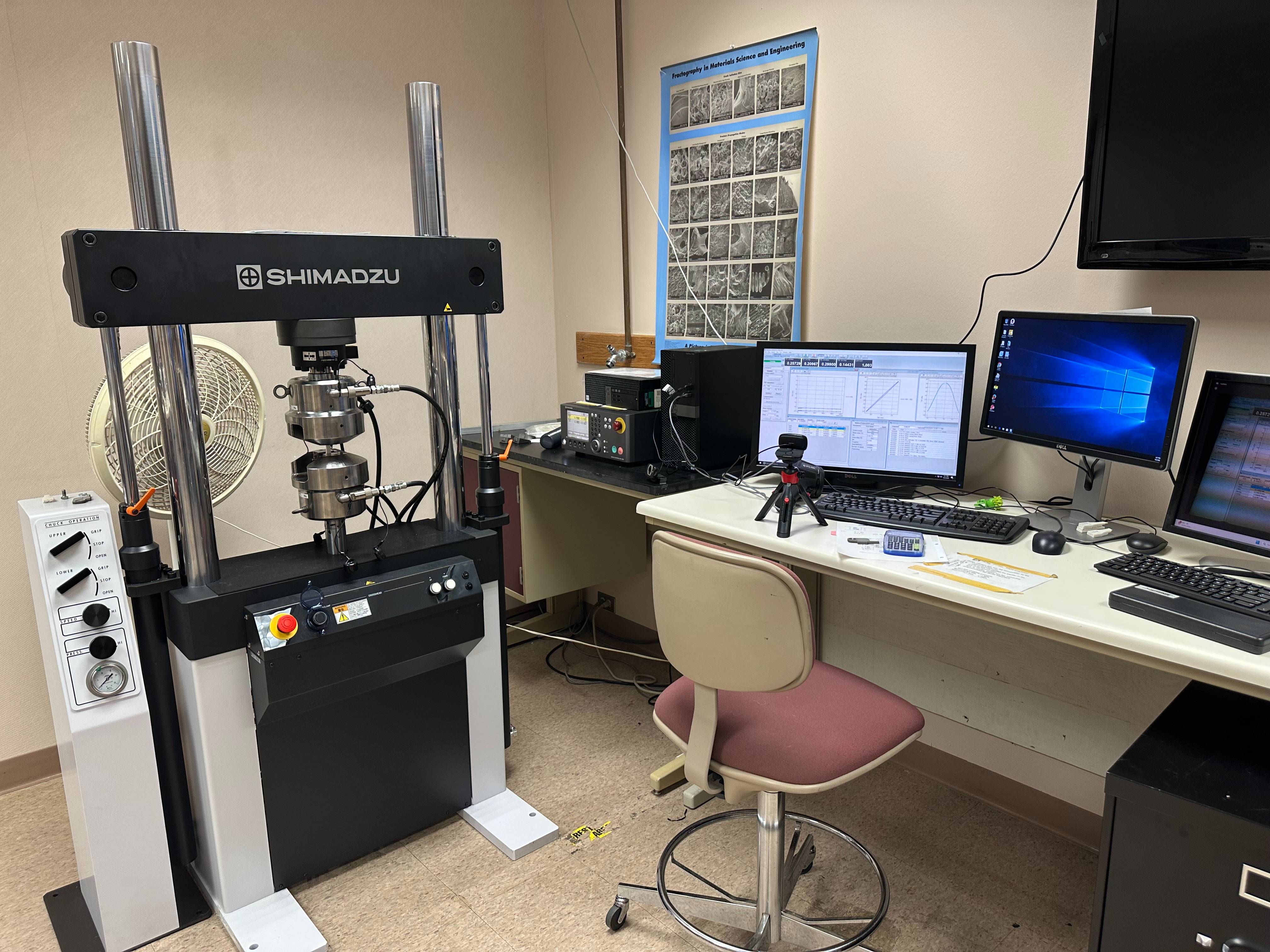

EQUIPMENT

|

1. Servopulser Servo Dynamic Systems EHF-E SERVOPULSER, 50KN, ± 50 mm from Shimadzu Features include:

|

|

|

3. Axial Extensometers For different specimen sizes:

|

|

| 3. Rotating Bending |

|

| 4. Optical Microscopy |

|

| 5. Hardness Tester |

|

| 6. Infrared Camera |

|

Academic Partners:

Orgnizational Partners:

|

|

Journal Publications:

- Dyer, K., Amjadi, M., Shao, S., Shamsaei, N., & Molaei, R., "Understanding fatigue of additively manufactured TPMS metallic metamaterials: Experiments and modeling". Additive Manufacturing, 2025, 104966. https://doi.org/10.1016/j.addma.2025.104966.

- Amjadi, M.; Fatemi, A.,” A critical plane approach for multiaxial fatigue life prediction of short fiber reinforced thermoplastic composites”. Composites Part A: Applied Science and Manufacturing, 2024. 180: p. 108050.

- Amjadi, M.; Fatemi, A.,” A Fatigue Damage Model for Life Prediction of Injection Molded Short Fiber Reinforced Thermoplastic Composites”. Polymers. 2021, 13, 2250.

- Amjadi, M.; Fatemi, A.,”Tensile Behavior of High-Density Polyethylene Including the Effects of Processing Technique, Thickness, Temperature, and Strain Rate”. Polymers 2020, 12, 1857.

- Amjadi, M.; Fatemi, A.,” Creep and fatigue behaviors of High-Density Polyethylene (HDPE): Effects of temperature, mean stress, frequency, and processing technique”. International Journal of Fatigue. 2020; 141: 105871. doi: 10.1016/j.ijfatigue.2020.105871.

- Amjadi, M.; Fatemi, A. Creep behavior and modeling of high-density polyethylene (HDPE). Polymer Testing 2021, 94, 107031, doi: 10.1016/j.polymertesting.2020.107031.

- Amjadi, M.; Fatemi, A.,” Multiaxial Fatigue Behavior of Thermoplastics Including Mean Stress and Notch Effects: Experiments and Modeling”. International Journal of Fatigue. 2020; 136: 105571. doi: 10.1016/j.ijfatigue.2020.105571.

- Amjadi, M.; Fatemi, A.,” Multiaxial Fatigue Behavior of High-Density Polyethylene (HDPE) Including Notch Effect: Experiments and Modeling”. ICMFF12 - 12th International Conference on Multiaxial Fatigue and Fracture; MATEC Web of Conferences. 2019; 300: 05001. doi: 10.1051/matecconf/201930005001.

- Amjadi M, Nikkhoo M, Khalaf K, et al., “An in silico parametric model of vertebrae trabecular bone based on density and microstructural parameters to assess risk of fracture in osteoporosis”. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine. 2014;228(12):1281-1295. doi:10.1177/0954411914563363.

Conferences:

- Amjadi, M, Brayden May, Genya Ohama, and Minh Hoang Tran; “Fatigue Behavior of Additively Manufactured PA6-GF TPMS Structures using FDM”, the ASTM International Conference on Advanced Manufacturing, Atlanta, GA, 2024.

- Molaei, R, Amjadi, M; “Fatigue Behavior of Additively Manufactured Titanium TPMS Structures using Selective Laser Melting”, the ASTM International Conference on Advanced Manufacturing, Atlanta, GA, 2024.

- Amjadi, M; Molaei, R, “A Comparison between Additive Manufacturing and Injection Molding Techniques”, the ASTM International Conference on Advanced Manufacturing, Washington, DC, 2023.

- Amjadi, M.; Fatemi, A.,” A Critical Plane Fatigue Damage Model for Multiaxial Fatigue Life Prediction of Injection MoldedShort Fiber Reinforced Thermoplastic Composites”. 13th International Conference on Multiaxial Fatigue and Fracture (ICMFF13), New Orleans, LA, USA, 2022.

- Amjadi M, Fatemi A., “Multiaxial Fatigue Behavior of Thermoplastics; Experimental Study and Modeling”. New trends in fatigue and fracture - NT2F19, Tucson, Arizona, USA, 2019.

- Amjadi, M.; Fatemi, "Fatigue Behavior of High-Density Polyethylene: Effects of Temperature, Mean Stress, and Manufacturing Method," 12th International Fatigue Congress (FATIGUE 2018), Poitiers Futuroscope-France, May 2018.

- Promoting Electric Propulsion” (PEP) boat races:

- PEP 2025: Two for Two: ATU Engineers Bring Trophies Home

- PEP 2024: ATU Top 2 in National Electric-Powered Boat Race

|

Read more about Arkansas Tech Engineeering Team at PEP Competition here: American Society of Naval Engineers > ArkansasTech

Sponsered by American Society of Naval Engineers.